According to the program on Thursday, each group went to the cultivation fields in the morning and, in the afternoon, to a factory. Fortunately, the press accreditation has allowed us to move freely, allowing us to visit the Tabacaleras that we know less, without being bound to the group.

We stopped at A.S.P. de Nicaragua, the only one in the whole country to grow tobacco plants with the „floating“ system. Before entering the cultivation area (this too, like that of Victor Calvo, was protected by sheets covering the entire fields), we were asked to wet the soles of the shoes with a chlorine solution in a tub. The areas destined for the seedlings looks like a sort of greenhouse, built with plastic for the roof and sheets for the walls, within which, as far as the eye can see, there are small plants of tobacco, that are only a few centimeters tall.

They are placed in a type of grid (each grid contains 142 seedlings), which floats in a 15 cm high tank. Each shed can accommodate up to 169,400 small tobacco plants that, multiplied by the 440 acres of the company, become about 12 million seedlings in a year of cultivation. However, not all will then be planted into the ground, because between 5 and 20% do not meet the minimum standards of the company.

Afterwards, the group we joined headed to “Cigar Box”, a company that, as the name suggests, takes care of making the boxes of many of the brands produced in Nicaragua and beyond. We found out that, indicatively, the average price of a box, for the company that commissions them, ranges around $9 per piece.

Lunch was held at “Cigar Ring“, in a huge outdoor space, shaded by an imposing metal structure and a white cover.

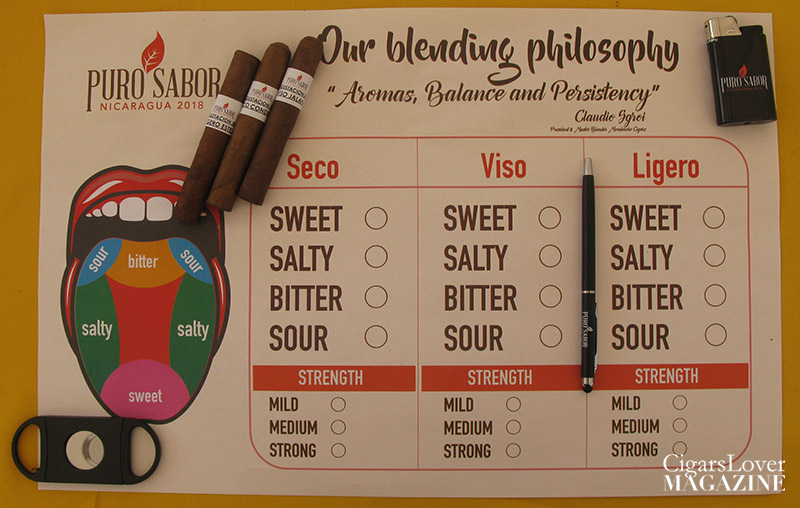

The cigars that were handed out were the Emerald Cigar (made by Plasencia), the Oliva Series V Melanio Gran Reserva Limitada and, lastly, three small cigars (petit corona sized) made exclusively with Seco Condega, Viso Jalapa and Ligero Estelì. The latter three were necessary for a tasting that was guided by Claudio Sgroi, president and master blender of Mombacho. The aim was to make participants appreciate the characteristics of each tobacco that, by themselves, are not enough to make a good cigar. At the end of the cata, as Italians, we were proud to hear the the applause from all the participants towards Claudio.

After the tasting and a quick American coffee, we left for the Padron manufacture, following a large group of aficionados of the Dominican Republic. Padron is a larger factory than one could imagine and entering the rolling gallery, the workplace of dozens of torcedors, makes always a great impact. The tour was conducted by Jorge Padron himself.

After that, we moved to the La Corona factory, where the HR (Hirochi Robaina) are produced. This factory is a complete opposite to Padron’s, it is small but well kept and organized, with a bright and welcoming ambience. In the Escaparate (or aging room) we got a glimpse of a Lancero sized HR, which are going to be launched soon. Before we leaving, a Cuban coffesito was offered.

Still not completely satisfied, our group explicitly asked the Nicaraguan guide (always with an indescribable and noisy joy) to be led to the Padron fields, where, once again, Jorge made himself available for a quick tour and numerous photos with the participants .

Dinner was held under the starry sky of Estelì, in the plaza Domingo Gadea: the requested dress code was the “White Guayabera” (included in the welcome package), a white linen shirt with a Korean collar that all the participants wore. The evening was inaugurated with a moment of commemoration for Josè Padron and Gilberto Oliva, both marked the history of the tobacco cultivation in Nicaraguan, which was followed by an emotional minute of silence.

The evening was then lifted by live Latin American music, a folk show, and cigars of course. They were handed out by the graceful señoritas: Rocky Patel Vintage 2006 San Andres, New World Puro Especiales by AJ Fernandez (Nr. 2 of the Awards 2017 for Nicaragua) and a Robusto by Omar Ortez.